Gutterseal – Liquid Gutter Liner

At last, a liquid gutter liner that actually works!

The Liquasil Gutterseal System is suitable for metal, cast iron, concrete and asbestos cement gutters.

It includes 3 components: our marine-grade anti-corrosion primer, a specially formulated sealer for the joints and our unique single-coat silicone finish to create a seamless, leak-free finish.

Gutterseal Installation Instructions

Liquid Gutter Liner & Gutter Repair System

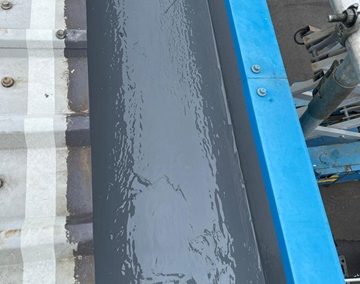

The Liquasil liquid gutter liner system forms a completely seamless and highly flexible lining that will eliminate leaks.

Step1: Liquasil’s marine-grade SWT Primer, is applied to all steel elements to prevent rust breakthrough.

Step 2: All joints are sealed with Non-Sag Sealer, a unique, highly flexible silicone compound.

Step 3: The whole gutter is coated with Liquasil one to provide a permanent, seamless and leak-free finish.

The Gutterseal system is suited to the most complex of gutter configurations, because unlike physical gutter liners, it goes around corners and is completely seamless. One applied, there are no weak spots for leaks to develop.

The Liquasil liquid gutter lining system has a product warranty of 15 years as standard.

We call our gutter liner system “Gutterseal” – a generic name to encompass the entire system, though it is made up of a small number of component parts.

Leakage at the joints is a common problem for industrial and commercial property gutters, which is why Non-Sag Sealer is included in the Gutterseal system. It eliminates joint leaks at their source, without the need to remove any fixings or replace rotted seals.

Example Liquid Gutter Lining Projects

Physical or Liquid Gutter Liner?

The difference between a physical gutter liner and a liquid gutter liner is that the physical liner is essentially a gutter within a gutter, whereas the liquid liner is something that is permanently bonded to the surface.

A liquid gutter liner is often the best option for resealing industrial and commercial gutters, but there are some circumstances where it may be more desirable to install a physical gutter liner instead.

Physical gutter liners are usually made from a plastic based material that is made to measure for each installation and then rolled out in-situ.

The main advantage of such a system is that no structural or other repair is necessary to the original gutter before installation.

This speeds up installation, especially on straight, larger girth gutters.

In most cases, outlets (even siphonic outlets), corners and T-Junctions will be custom-moulded by the manufacturer and the gutter itself supplied on a seamless roll. This type of gutter lining is usually held in place with clips.

Sometimes water can still get beneath a physical liner and cause the original substrate to deteriorate. Trapped water between a physical liner and the substrate will cause corrosion.

With our liquid gutter liner, the gutter is first cleaned and then dried thoroughly. Surface rust is treated and all joints and holes are sealed before the liquid liner is brushed or rolled into the gutter.

The liner dries in just a few hours and is fully cured in a day or two depending on the weather and temperature. The end result is a seamless, fully bonded liner that becomes part of the original gutter.

Each type of gutter liner has its advantages and disadvantages. Our building surveyors will be happy to discuss your project and help you decide which is best for your project.

Cleaning A Gutterseal Lined Gutter

Liquid lined gutters will still be susceptible to soiling and debris accumulation in the same way as any other gutter.

Cleaning is a relatively simple process, as long as care is taken not to damage the lining.

The Gutterseal liner system is made from silicone, which is a soft coating, with a thickness of around 750 microns to 1mm.

To ensure that the coating system is not damaged, please avoid using sharp scrapers, particularly metal, as these could damage the coated surface.

Leaf and other debris should be manually removed from the gutter (gutter vacuum cleaners may be used) and then the gutter should be rinsed through with clean water.

Low pressure jet washes may be used to remove any surface algae that might be present and Liquasil can also provide a compatible anti-fungicidal wash to kill any fungal growth that might be present on the surface.

All gutters should be examined and cleaned at least annually and more frequently if the premises are in close proximity to trees, or if nesting birds are present on the roof.

If any damage is noted to the gutters, Liquasil can provide additional product to be applied to the damaged area(s).

Gutter Liner Project Galleries

FAQs

What is Gutterseal?

Gutterseal is the name we give to our liquidgutter lining system.

It comprises three components:

- SWT Primer – to treat and prevent corrosion

- Non-Sag Sealer – to seal joints and fixings

- Liquasil One – which forms the full lining and makes the whole liner seamless

How long does it take to install?

Installation time will depend on the size of the gutter, so most industrial gutters are done in stages.

The first stage is to clean out the gutter and prepare the surface, removing all debris and heavy corrosion.

Then the gutter has to be primed and the primer can take severeal hours, or even overnight to dry out.

Assuming that the primed surfaces are bone dry, the Non-Sag Sealer can be applied to the joints and fixings and then immediately overcoated, with the rest of the gutter using Liquasil One.

Why does the gutter have to be dry before it is top-coated?

The top coat products (Non-Sag Sealer and Liquasil One are made from silicone.

Because silicone repels water, it can only be applied to bone-dry surfaces.

Any moisture that is present in the gutter will result in a failure in that area, meaning that the coating will simply peel away.

What happens if the new liner gets wet before it is cured?

If it rains on the newly coated gutter, the surface will become pitted.

This might not affect the performance of the new coating.

However, if the gutter becomes full of water, the product will not cure and may debond from the surface.

Our recommendation is to only install the liquidgutter liner when you know the weather conditions are going to remain dry for at least 4 hours.

Does all surface rust need to be removed before coating?

All loose and flaking material must be removed as far as reasonably practicable before the surface is treated with SWT Primer.

However, the primer is tolerant of surface rust (light gingering) so this may remain if present.

Gutter Liner Project Galleries

FAQs

What is Gutterseal?

Gutterseal is the name we give to our liquidgutter lining system.

It comprises three components:

- SWT Primer – to treat and prevent corrosion

- Non-Sag Sealer – to seal joints and fixings

- Liquasil One – which forms the full lining and makes the whole liner seamless

How long does it take to install?

Installation time will depend on the size of the gutter, so most industrial gutters are done in stages.

The first stage is to clean out the gutter and prepare the surface, removing all debris and heavy corrosion.

Then the gutter has to be primed and the primer can take severeal hours, or even overnight to dry out.

Assuming that the primed surfaces are bone dry, the Non-Sag Sealer can be applied to the joints and fixings and then immediately overcoated, with the rest of the gutter using Liquasil One.

Why does the gutter have to be dry before it is top-coated?

The top coat products (Non-Sag Sealer and Liquasil One are made from silicone.

Because silicone repels water, it can only be applied to bone-dry surfaces.

Any moisture that is present in the gutter will result in a failure in that area, meaning that the coating will simply peel away.

What happens if the new liner gets wet before it is cured?

If it rains on the newly coated gutter, the surface will become pitted.

This might not affect the performance of the new coating.

However, if the gutter becomes full of water, the product will not cure and may debond from the surface.

Our recommendation is to only install the liquidgutter liner when you know the weather conditions are going to remain dry for at least 4 hours.

Does all surface rust need to be removed before coating?

All loose and flaking material must be removed as far as reasonably practicable before the surface is treated with SWT Primer.

However, the primer is tolerant of surface rust (light gingering) so this may remain if present.

There are many types of industrial gutter liner on the market.

Some are better than others, but Liquasil’s Gutterseal is simpler and more robust than most.

Call us on 0121 709 5352 for an informal discussion about your project.